Fourmilab's Coruscating, Actinic,

(partially) Nuclear-Powered Christmas Lights

December 10th, 2004

'Tis the season to put up the Christmas lights and, as usual,

confront the problem of dead series-strings of incandescent bulbs.

Now, if you're an engineer like me, you've probably developed a

pretty strong sense over the years about how the world works. This

hindbrain reality detector will probably rule out ever finding a

string of 12 bulbs in series in which three or four have

burned out filaments, but in fact this is common when repairing such

lights. What's going on? I'm not entirely sure—the most plausible

explanation seems to be that when a filament opens, you can often get

the string working again by tapping it against a window (or other

hard object). This will sometime jog an open filament back into

contact, so the string lights again until another filament opens,

which can sometimes be remedied in the same way. When the thing

resolutely refuses to light and you take it to the bench to repair,

you find multiple dead bulbs, many with obvious open filaments when

viewed through a 10× magnifier. On the other hand, the explanation

may be tiny filament snipping gremlins from the fourth dimension who

materialise inside the bulbs when the lights are stored in the attic

waiting for next year. But this engineer is not going there.

'Tis the season to put up the Christmas lights and, as usual,

confront the problem of dead series-strings of incandescent bulbs.

Now, if you're an engineer like me, you've probably developed a

pretty strong sense over the years about how the world works. This

hindbrain reality detector will probably rule out ever finding a

string of 12 bulbs in series in which three or four have

burned out filaments, but in fact this is common when repairing such

lights. What's going on? I'm not entirely sure—the most plausible

explanation seems to be that when a filament opens, you can often get

the string working again by tapping it against a window (or other

hard object). This will sometime jog an open filament back into

contact, so the string lights again until another filament opens,

which can sometimes be remedied in the same way. When the thing

resolutely refuses to light and you take it to the bench to repair,

you find multiple dead bulbs, many with obvious open filaments when

viewed through a 10× magnifier. On the other hand, the explanation

may be tiny filament snipping gremlins from the fourth dimension who

materialise inside the bulbs when the lights are stored in the attic

waiting for next year. But this engineer is not going there.

Regardless of the cause, it is intensely irritating when one of these strings of lights

fails. Each one contains 12 “grain of wheat” bulbs, driven with 24 Volts AC

from a transformer, so the voltage drop across each bulb is about 2V. These “light

curtains” can be installed inside or outside, so the bulbs in the strings have heat shrinkable

tubing along the base which makes it difficult to test for blown bulbs. Generally,

it takes between 30 minutes and an hour to repair a dead string. First you replace all

the bulbs with visibly open filaments, but usually there are one or two dead bulbs

which look OK under the magnifier, and can only be found to be bad by stripping the

wire on either side and testing with an ohmmeter.

from a transformer, so the voltage drop across each bulb is about 2V. These “light

curtains” can be installed inside or outside, so the bulbs in the strings have heat shrinkable

tubing along the base which makes it difficult to test for blown bulbs. Generally,

it takes between 30 minutes and an hour to repair a dead string. First you replace all

the bulbs with visibly open filaments, but usually there are one or two dead bulbs

which look OK under the magnifier, and can only be found to be bad by stripping the

wire on either side and testing with an ohmmeter.

Now, you might say, “Why be so bloody cheap? Just pitch a string when it dies and

install a new one!” Well, first of all, I am bloody cheap, and I really

don't like the idea of throwing away nine or ten perfectly good bulbs, along with

the connector, wire, etc. because a few bulbs have failed. But in addition,

replacement bulb strings aren't reliably available—it seems like they change

the connectors every few years, so you still have to solder the connector

from the old string to the new one. And of course what they really want you

to do is buy a whole new set with the transformer, etc. and that is right out

as far as I'm concerned.

Still, I do like the lights in the window, and neighbours remark upon

how welcoming illuminated Fourmilab is when driving into the

village on dark, foggy nights in the Christmas season. What to do?

Well, how about that time-proven, all-purpose solution: smashing the problem

to death with technology! In this case, replacing the incandescent bulbs with

light emitting diodes (LEDs), making compatible strings which are completely

interchangeable with the existing ones. LEDs, properly treated, almost never

fail, and they also emit far more light per milliampere of current

consumed than incandescents; they last forever, run cool, and use less

power—win, win, win. Of course, they do cost more—quite a bit

more, in fact, but that's a capital expense which can be amortised over

the decades they'll last and is, in any case, easily recouped if you consider

the time and irritation you'll save not having to repair or replace incandescents.

Well, how about that time-proven, all-purpose solution: smashing the problem

to death with technology! In this case, replacing the incandescent bulbs with

light emitting diodes (LEDs), making compatible strings which are completely

interchangeable with the existing ones. LEDs, properly treated, almost never

fail, and they also emit far more light per milliampere of current

consumed than incandescents; they last forever, run cool, and use less

power—win, win, win. Of course, they do cost more—quite a bit

more, in fact, but that's a capital expense which can be amortised over

the decades they'll last and is, in any case, easily recouped if you consider

the time and irritation you'll save not having to repair or replace incandescents.

Based on extensive research (flipping through the

Distrelec

catalogue), I chose the

Kingbright

W7114PWC/H white (actually, it

has a bluish cast) high-intensity LED. This device is typically

operated with a forward voltage of 3.7V, which I derated to 3.6V

since I didn't need the full intensity (which is almost blinding

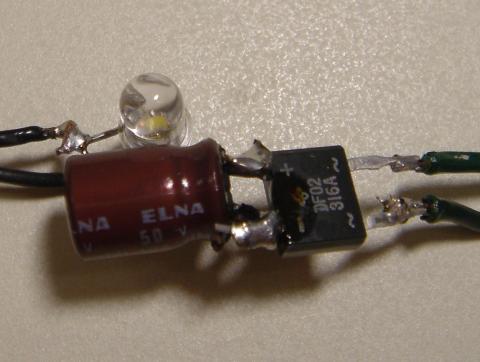

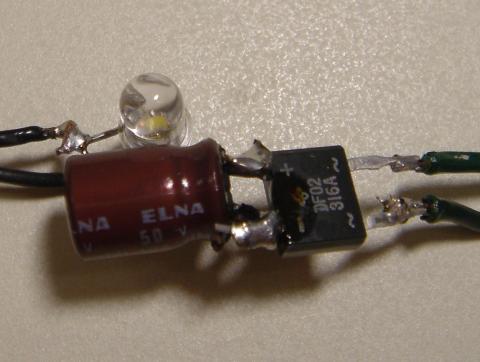

head-on). To power each string, I fabricated a head-end consisting

of a full-wave bridge rectifier and a 100µF smoothing capacitor.

Driven with 24 VAC (RMS), this produces about 37.8V DC with Fourmilab's

typical line voltage of around 230V. Dividing by the 3.6V forward voltage

of the LEDs, we find that 10.5 LEDs in series will yield the desired

current.

What, saw an LED in half? No problem—just connect 10 LEDs in series with two

in parallel at the end of the string! Now, veteran electrical engineers will

recoil in horror at the thought of connecting forward-biased diodes in parallel

without a load-balancing resistor but, in fact, it works just fine. As long as

you use diodes with the same part number from the same manufacturer, you can see

a difference at low current, but when they approach operating load they

behave identically.

What, saw an LED in half? No problem—just connect 10 LEDs in series with two

in parallel at the end of the string! Now, veteran electrical engineers will

recoil in horror at the thought of connecting forward-biased diodes in parallel

without a load-balancing resistor but, in fact, it works just fine. As long as

you use diodes with the same part number from the same manufacturer, you can see

a difference at low current, but when they approach operating load they

behave identically.

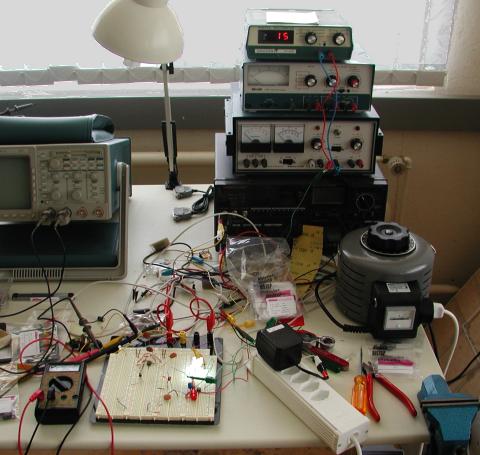

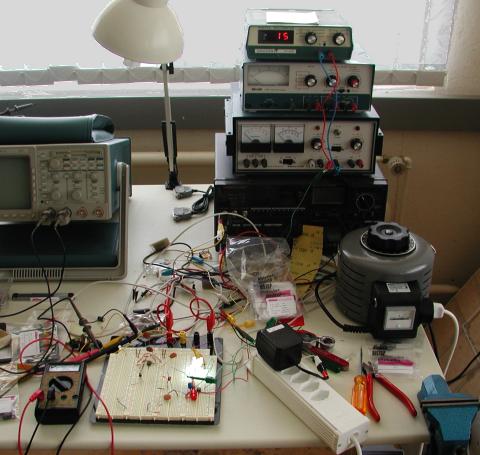

Here, I've made a “space frame” circuit, soldering the leads from the

string connector directly to the rectifier, and the rest of the string

to the other side. The leads on these DIPs don't survive many flexures,

so it may be wiser to fabricate the circuit on perf-board to keep the IC

from losing its legs. The pictures above show the first replacement LED

string installed with legacy incandescents; as the incandescents burn out,

I'll transition over to all LEDs.

One difference between LEDs and incandescents is that incandescent lamps have an

isotropic (all-aspect) light emission, while most LED packages strongly “beam” the light

along one axis. In fact, the LEDs are so bright that this isn't a problem—even the

off-axis emission from the LED is as bright as the incandescents, as you can see

in the exterior shot above, taken through thick freezing ground fog.

If the LEDs are mounted in more or less random orientation, their

principal beams will be be distributed through space. This causes the

wall of light to appear to “sparkle” as a moving observer passes through

the beams of the various LEDs, which is a nice effect. My next experiment

will be “frosting” the LEDs to diffuse the light by dipping them in a mixture of Epsom

salt (MgSO4) and beer. Re-visit this page in a couple of days to see

how that worked!

Switzerland

Electricity by Source |

|---|

| Hydro | 59.5% |

|---|

| Nuclear | 37.1% |

|---|

| Fossil fuel | 1.3% |

|---|

| Other | 2% |

|---|

Fourmilab's Christmas lights, like everything electrical in

Switzerland, consume almost no fossil fuel. Electricity generation

in Switzerland is about 60% from hydroelectric power and 37%

nuclear. So more than every third electron that passes through

Fourmilab's Christmas lights is kicked along its way by nuclear

energy—green glowing cool!

This document is in the public domain. Permission to use,

copy, modify, and distribute this document for any purpose

and without fee is hereby granted, without any conditions

or restrictions. This document is provided “as is”

without express or implied warranty.

by John Walker

December 10th, 2004

'Tis the season to put up the Christmas lights and, as usual,

confront the problem of dead series-strings of incandescent bulbs.

Now, if you're an engineer like me, you've probably developed a

pretty strong sense over the years about how the world works. This

hindbrain reality detector will probably rule out ever finding a

string of 12 bulbs in series in which three or four have

burned out filaments, but in fact this is common when repairing such

lights. What's going on? I'm not entirely sure—the most plausible

explanation seems to be that when a filament opens, you can often get

the string working again by tapping it against a window (or other

hard object). This will sometime jog an open filament back into

contact, so the string lights again until another filament opens,

which can sometimes be remedied in the same way. When the thing

resolutely refuses to light and you take it to the bench to repair,

you find multiple dead bulbs, many with obvious open filaments when

viewed through a 10× magnifier. On the other hand, the explanation

may be tiny filament snipping gremlins from the fourth dimension who

materialise inside the bulbs when the lights are stored in the attic

waiting for next year. But this engineer is not going there.

'Tis the season to put up the Christmas lights and, as usual,

confront the problem of dead series-strings of incandescent bulbs.

Now, if you're an engineer like me, you've probably developed a

pretty strong sense over the years about how the world works. This

hindbrain reality detector will probably rule out ever finding a

string of 12 bulbs in series in which three or four have

burned out filaments, but in fact this is common when repairing such

lights. What's going on? I'm not entirely sure—the most plausible

explanation seems to be that when a filament opens, you can often get

the string working again by tapping it against a window (or other

hard object). This will sometime jog an open filament back into

contact, so the string lights again until another filament opens,

which can sometimes be remedied in the same way. When the thing

resolutely refuses to light and you take it to the bench to repair,

you find multiple dead bulbs, many with obvious open filaments when

viewed through a 10× magnifier. On the other hand, the explanation

may be tiny filament snipping gremlins from the fourth dimension who

materialise inside the bulbs when the lights are stored in the attic

waiting for next year. But this engineer is not going there.

from a transformer, so the voltage drop across each bulb is about 2V. These “light

curtains” can be installed inside or outside, so the bulbs in the strings have heat shrinkable

tubing along the base which makes it difficult to test for blown bulbs. Generally,

it takes between 30 minutes and an hour to repair a dead string. First you replace all

the bulbs with visibly open filaments, but usually there are one or two dead bulbs

which look OK under the magnifier, and can only be found to be bad by stripping the

wire on either side and testing with an ohmmeter.

from a transformer, so the voltage drop across each bulb is about 2V. These “light

curtains” can be installed inside or outside, so the bulbs in the strings have heat shrinkable

tubing along the base which makes it difficult to test for blown bulbs. Generally,

it takes between 30 minutes and an hour to repair a dead string. First you replace all

the bulbs with visibly open filaments, but usually there are one or two dead bulbs

which look OK under the magnifier, and can only be found to be bad by stripping the

wire on either side and testing with an ohmmeter.

Well, how about that time-proven, all-purpose solution: smashing the problem

to death with technology! In this case, replacing the incandescent bulbs with

light emitting diodes (LEDs), making compatible strings which are completely

interchangeable with the existing ones. LEDs, properly treated, almost never

fail, and they also emit far more light per milliampere of current

consumed than incandescents; they last forever, run cool, and use less

power—win, win, win. Of course, they do cost more—quite a bit

more, in fact, but that's a capital expense which can be amortised over

the decades they'll last and is, in any case, easily recouped if you consider

the time and irritation you'll save not having to repair or replace incandescents.

Well, how about that time-proven, all-purpose solution: smashing the problem

to death with technology! In this case, replacing the incandescent bulbs with

light emitting diodes (LEDs), making compatible strings which are completely

interchangeable with the existing ones. LEDs, properly treated, almost never

fail, and they also emit far more light per milliampere of current

consumed than incandescents; they last forever, run cool, and use less

power—win, win, win. Of course, they do cost more—quite a bit

more, in fact, but that's a capital expense which can be amortised over

the decades they'll last and is, in any case, easily recouped if you consider

the time and irritation you'll save not having to repair or replace incandescents.

What, saw an LED in half? No problem—just connect 10 LEDs in series with two

in parallel at the end of the string! Now, veteran electrical engineers will

recoil in horror at the thought of connecting forward-biased diodes in parallel

without a load-balancing resistor but, in fact, it works just fine. As long as

you use diodes with the same part number from the same manufacturer, you can see

a difference at low current, but when they approach operating load they

behave identically.

What, saw an LED in half? No problem—just connect 10 LEDs in series with two

in parallel at the end of the string! Now, veteran electrical engineers will

recoil in horror at the thought of connecting forward-biased diodes in parallel

without a load-balancing resistor but, in fact, it works just fine. As long as

you use diodes with the same part number from the same manufacturer, you can see

a difference at low current, but when they approach operating load they

behave identically.